Silicone Rubber Coefficient Of Friction

Most dry materials in combination have friction coefficient values between 0 3 and 0 6.

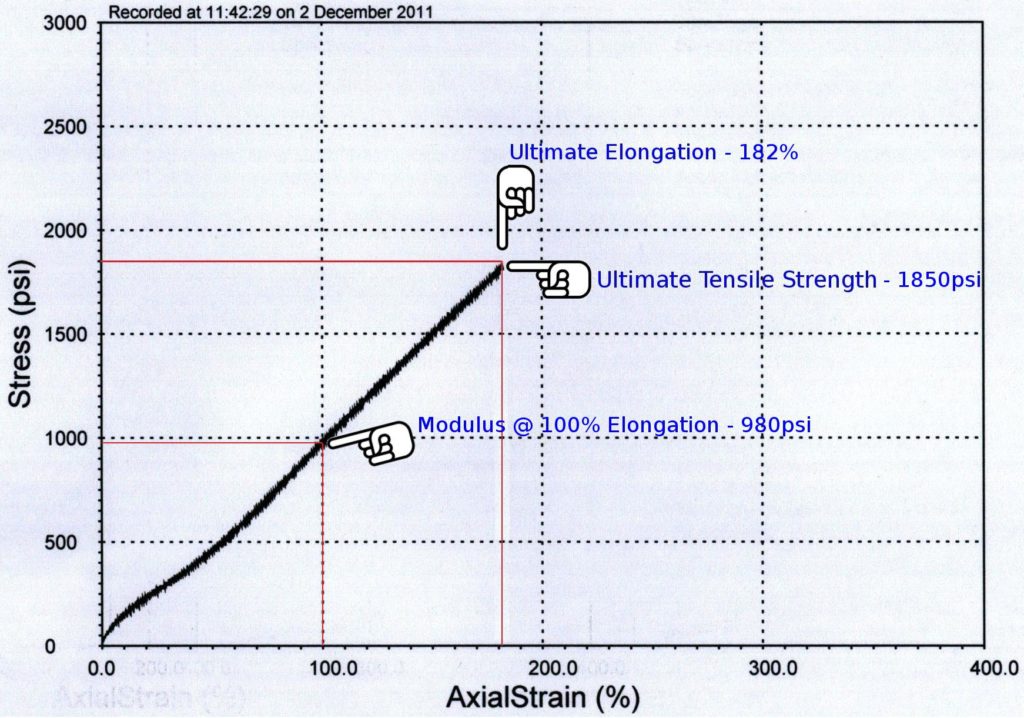

Silicone rubber coefficient of friction. The coefficient of friction of silicone rubber ranges from less than 0 25 to more than 0 75. Steel is about 10. Rubber in contact with other surfaces can yield friction coefficients from 1 to 2. Values outside this range are rarer but teflon for example can have a coefficient as low as 0 04.

N normal force between the surfaces n lb there are at least two types of friction forces. The coefficient of static friction typically denoted as μ s is usually higher than the coefficient of kinetic friction. Static friction is friction between two or more solid objects that are not moving relative to each other. The friction force is the force exerted by a surface when an object moves across it or makes an effort to move across it.

A liquid silicone rubber top coat can be used to improve surface friction of silicone elastomer parts. The frictional force can be expressed as. A value of zero would mean no friction at all an elusive property. The relatively high coefficient of friction of silicone elastomers can limit the range of applications of these materials.

F f μ n 1. Compared to steel silicone rubber is 2 to 7 times greater. Silicone is naturally quite tacky with a coefficient of friction of approximately 1 0 in many cases. μ static μ s or kinetic μ k frictional coefficient.

The texture can be used to reduce the co efficient of friction. Lower durometers have higher coefficients. These processes include applying a small amount of talc to the silicone surface and post curing the silicone in an oven for several hours. Another solution is the use of a low cof silicone coating applied to the surface and then cured to chemically bond the coating to the substrate for a non tacky surface.

On many of our products processes are applied to reduce the coefficient of friction. As medical device designers account for friction one solution is self lubricating liquid silicone rubber lsr which eliminates an extra step to apply lubrication. F f frictional force n lb. The force it takes to initiate movement between the silicone rubber and a steel panel static cof was measured as well as the force needed to keep the silicone rubber moving against.