Silicon Wafers 3 Micron For Solar Panel

The company s business ranges from silicon wafers cells and modules to complete photovoltaic power systems and its products are sold to over 120 countries and regions.

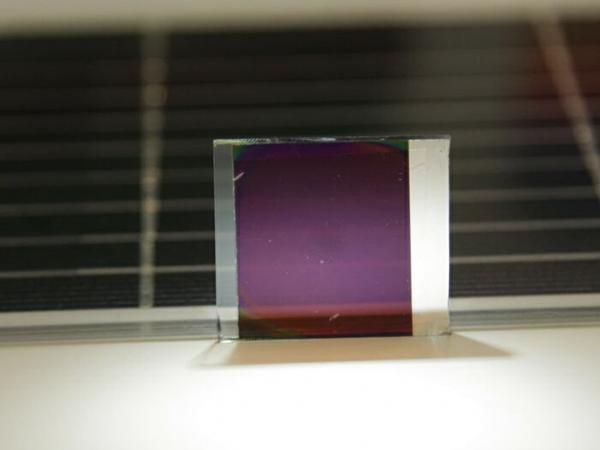

Silicon wafers 3 micron for solar panel. Rayton solar claims it can cut electronic grade silicon into wafers that are just 3 microns thick compared with standard silicon wafers that are up to 200 microns thick. In the same period the thickness of a c si wafer was reduced from 300 μm or microns to about 160 190 μm. Contact supplier silicon. Or email us your specs qty.

A 72 cell trina solar panel common in 2016 using m2 wafers averages about 6 5 ft long and 3 ft wide. Us 0 24 0 26 watt 10350 watts min. 40um surface solar silicon solar cell material top rated theoretical efficiencies as of 2015. We have in stock solar silicon waffers.

Yakub said he patented a. Jiangsu ideasolar co ltd. In electronics a wafer also called a slice or substrate is a thin slice of semiconductor such as a crystalline silicon c si used for the fabrication of integrated circuits and in photovoltaics to manufacture solar cells the wafer serves as the substrate for microelectronic devices built in and upon the wafer. Ja solar was founded in 2005.

It produces upwards of 380 w and weighs 50 lbs. The wafers serve then as substrate material for the solar cell. 156mm x 156mm n ph 100 res 1 5 ohm cm 200um as cut saw marks 15um diagonal length. Within the last ten years the amount of silicon used for solar cells declined from 16 to 6 grams per watt peak.

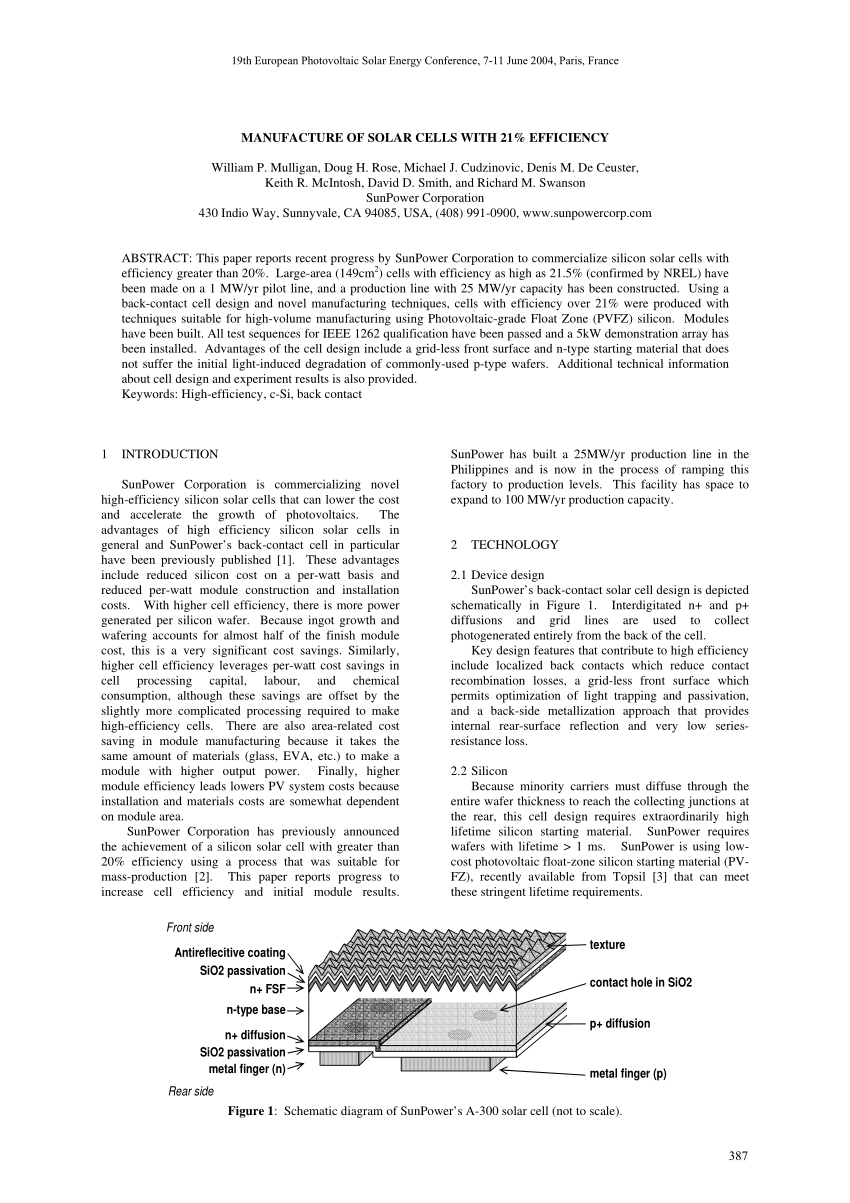

In both cases the generated material is cut to wafers by wire saws. It undergoes many microfabrication processes such as doping ion. The solar cells consists mainly of silicon and is called therefore thick film solar cell in contrary to thin film solar cells where the semiconductor layers are deposited on substrate of a different material. Today s silicon photovoltaic cells the heart of these solar panels are made from wafers of silicon that are 160 micrometers thick but with improved handling methods the researchers propose this could be shaved down to 100 micrometers and eventually as little as 40 micrometers or less which would only require one fourth as much silicon for a given size of panel.

The power output increases to 500 w and the larger panel weighs 65 lbs. Order 2 yrs. Order solar silicon wafers online and save. Crystalline silicon wafers are nowadays only 40 percent as thick as they used to be in 1990 when they were around 400 μm.