Sialon Ceramics Properties

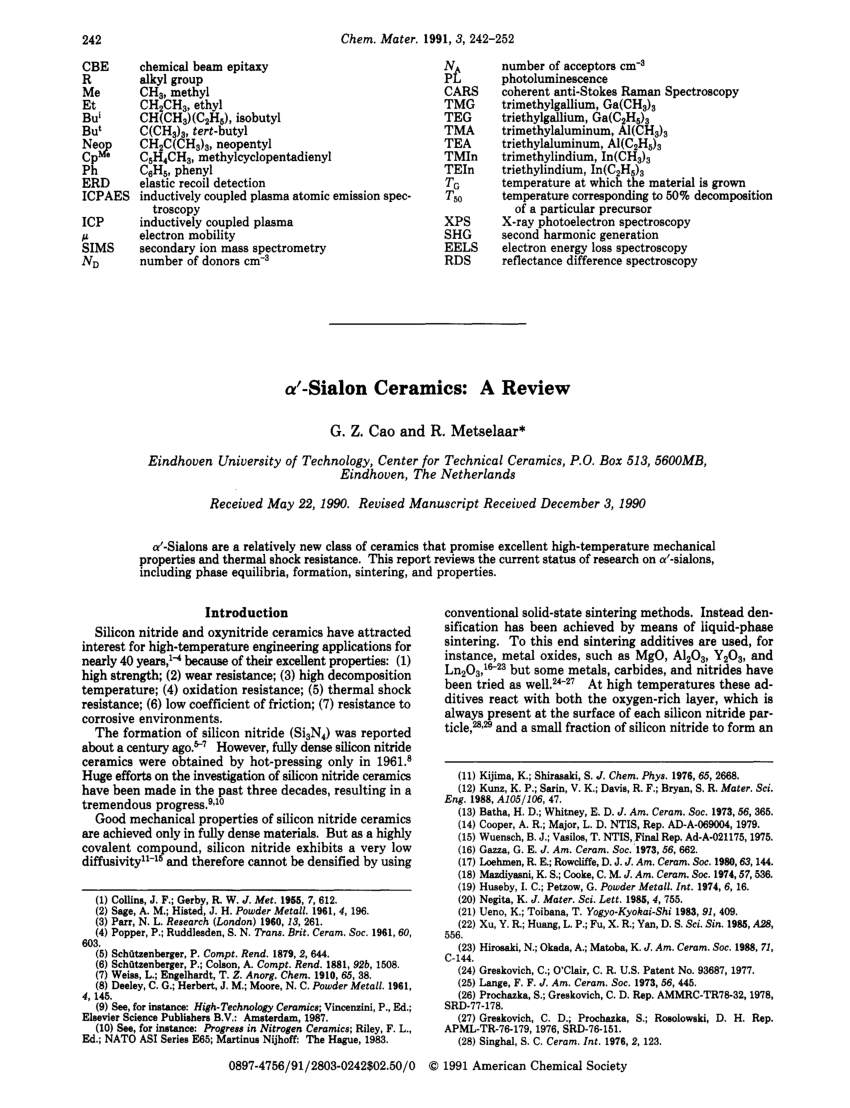

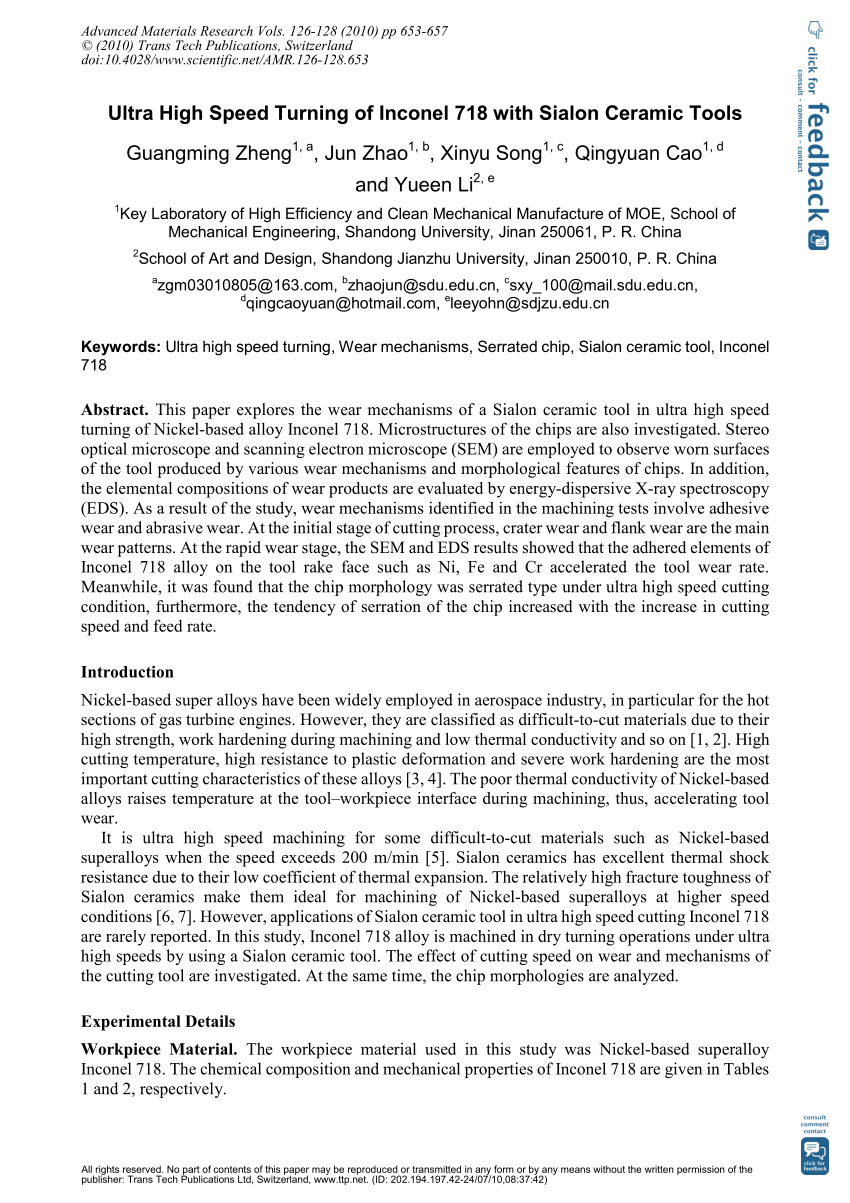

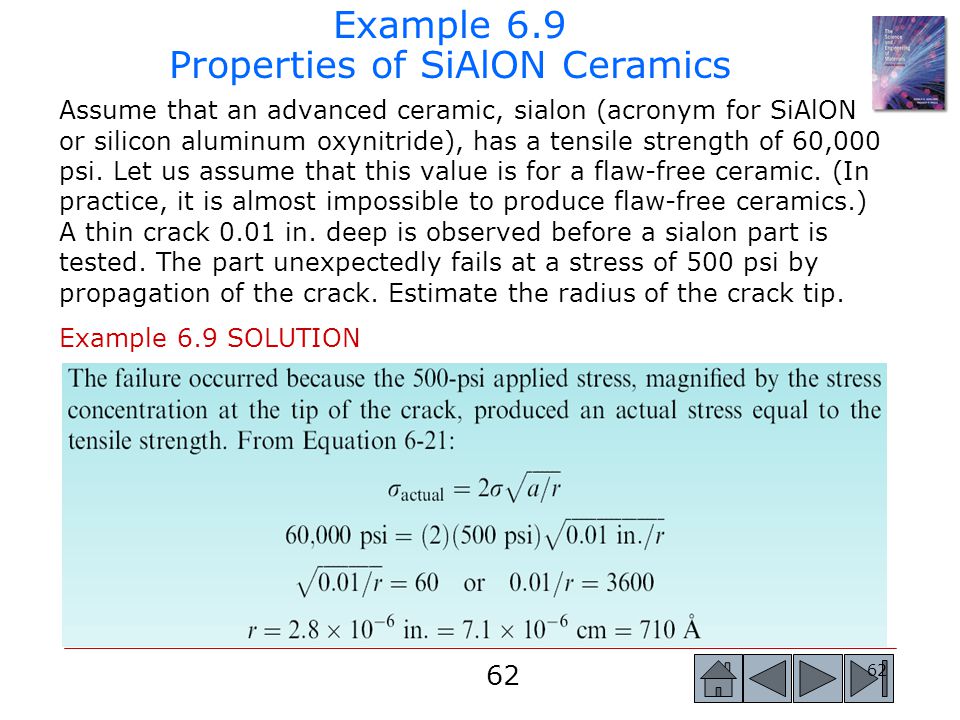

Zhuo tian the shrinkage phase composition and mechanical properties of ceramics with different β sialon main crystalline phases prepared by stereolithography ceramics silikaty 10 13168 cs 2020 0004 1 9 2020.

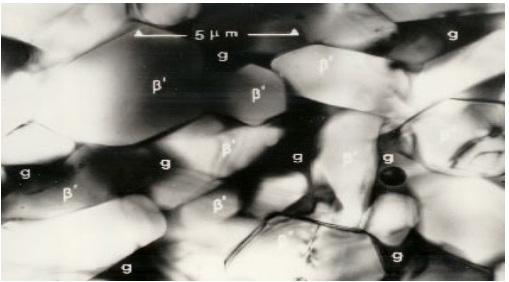

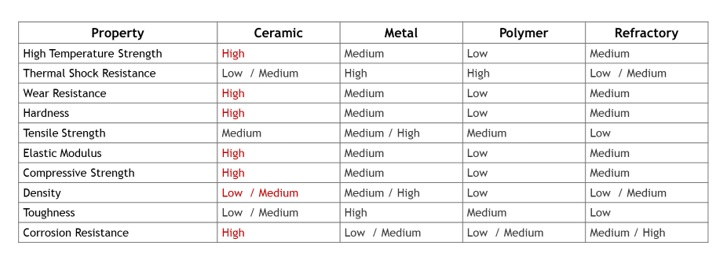

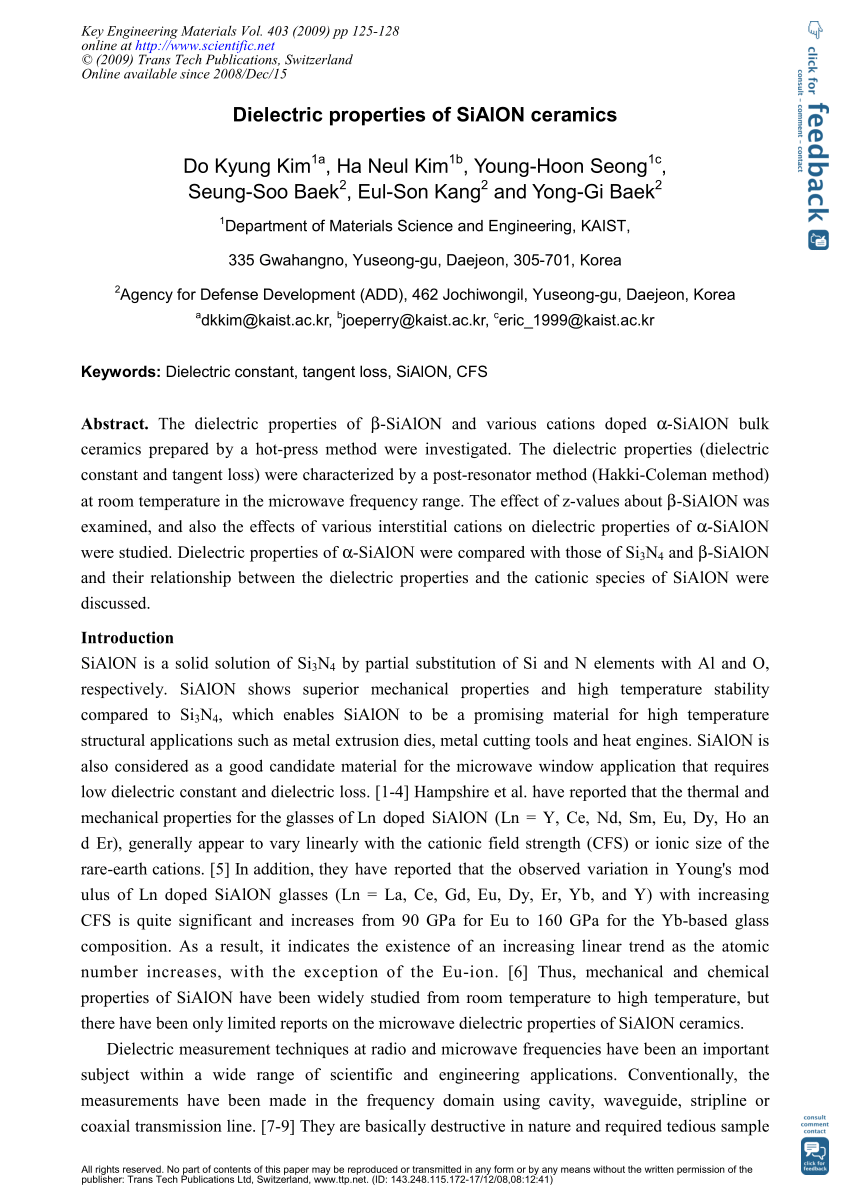

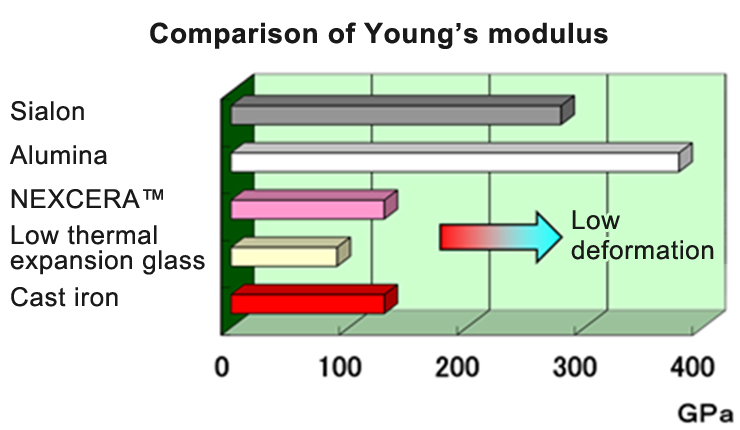

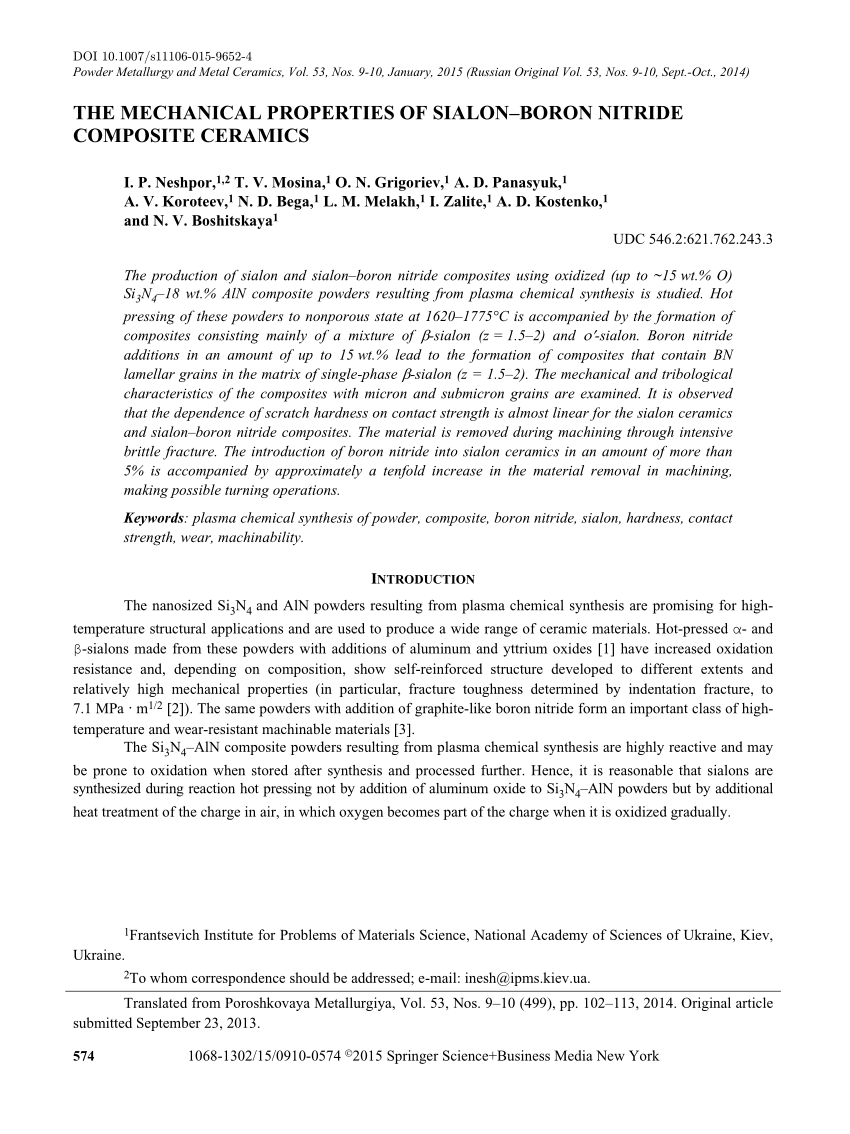

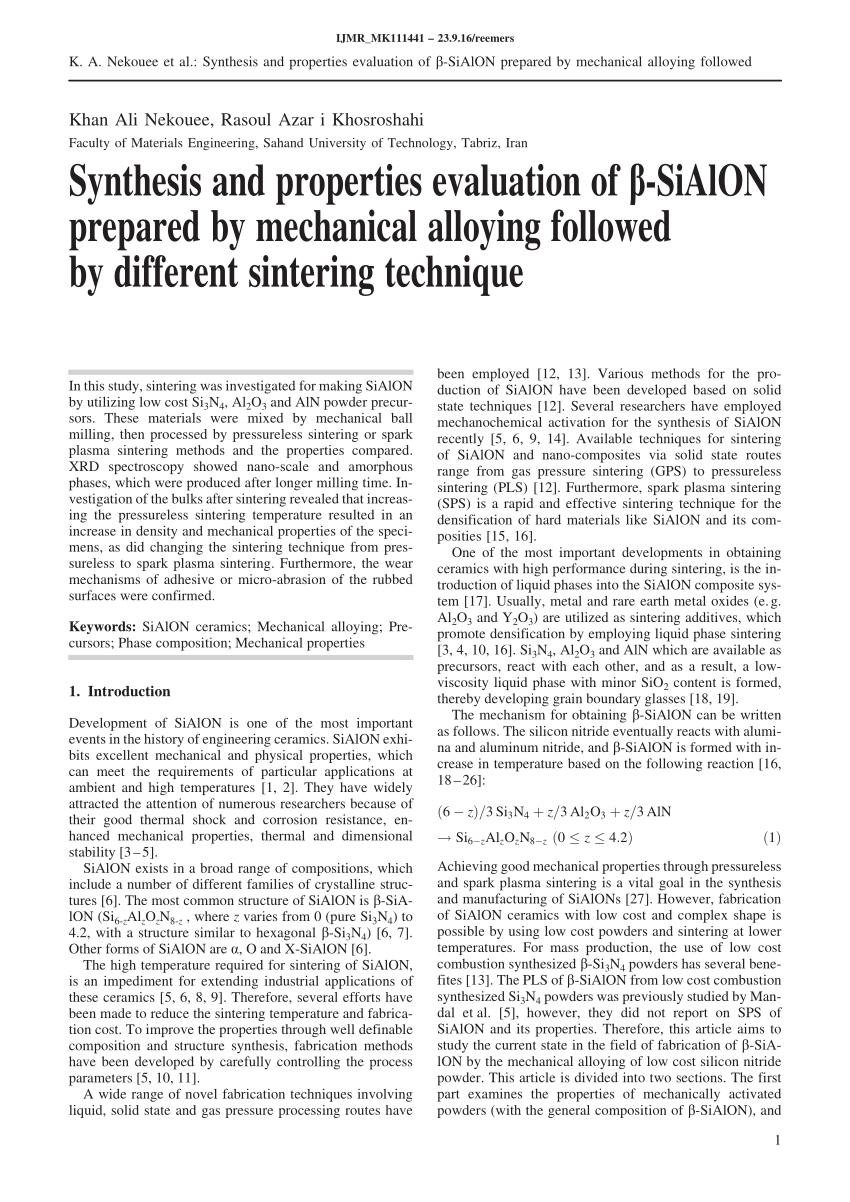

Sialon ceramics properties. Other applications include in the chemical and process industries and the oil and gas industries due to sialons excellent chemical stability and corrosion resistance and wear. As such it s properties include improved corrosion resistance to steel over other syalons outstanding thermal shock resistance and usable upto temperatures in excess of 1450 c. In the present work the results showed that composites sintered at different t2 temperature had similar phase assemblage and morphologies. Thus one can tailor the material to have a combination of the high strength and toughness of β sialon and the high hardness and high temperature properties of α sialon.

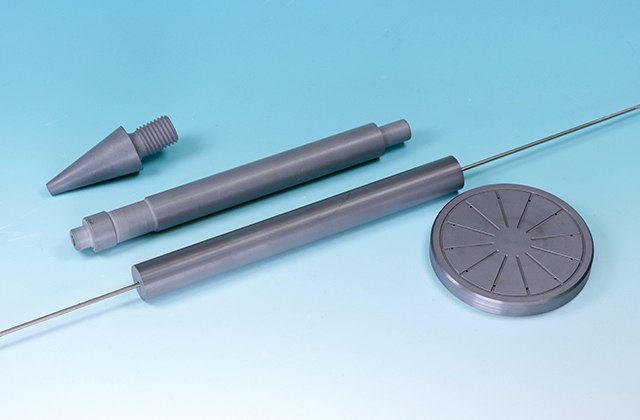

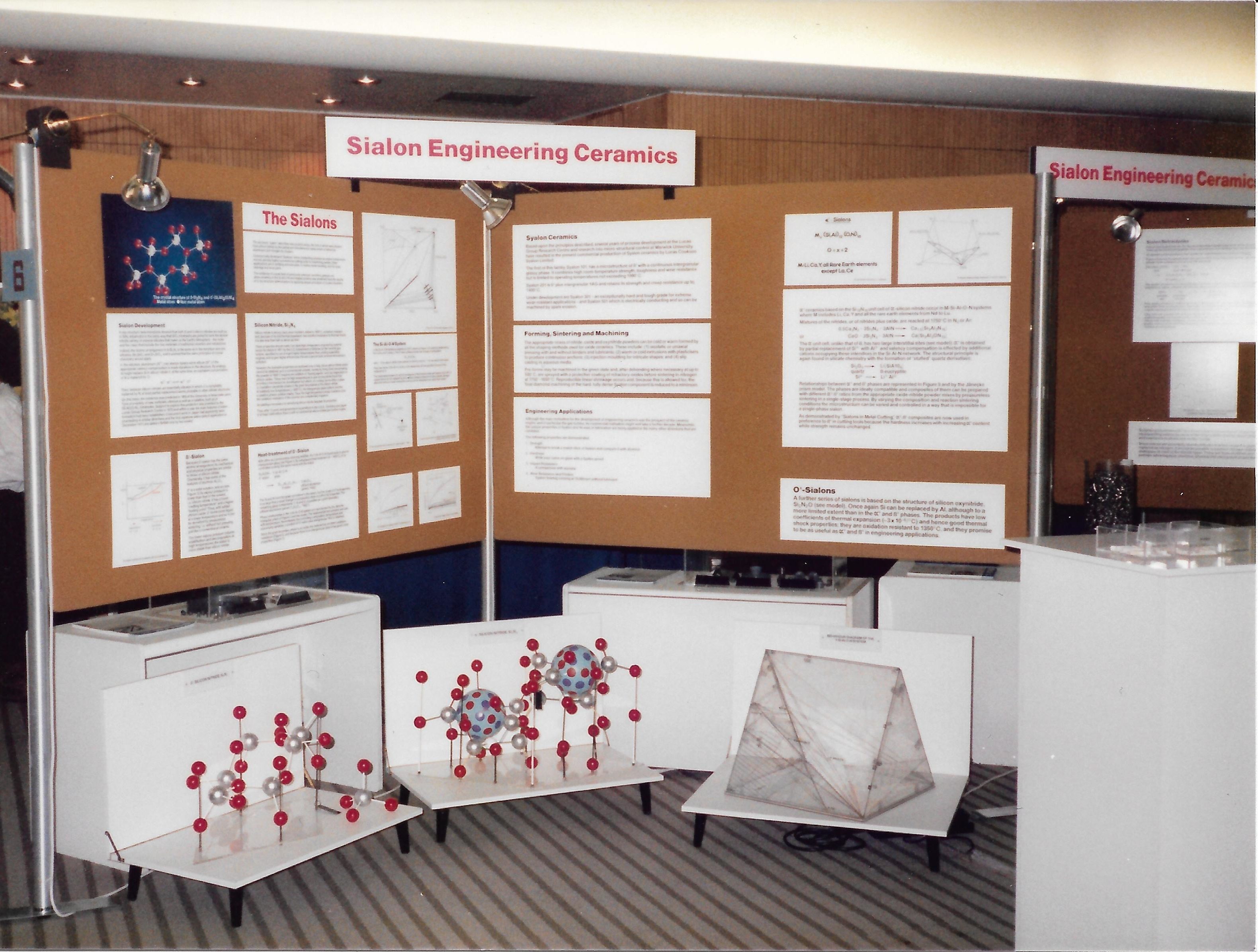

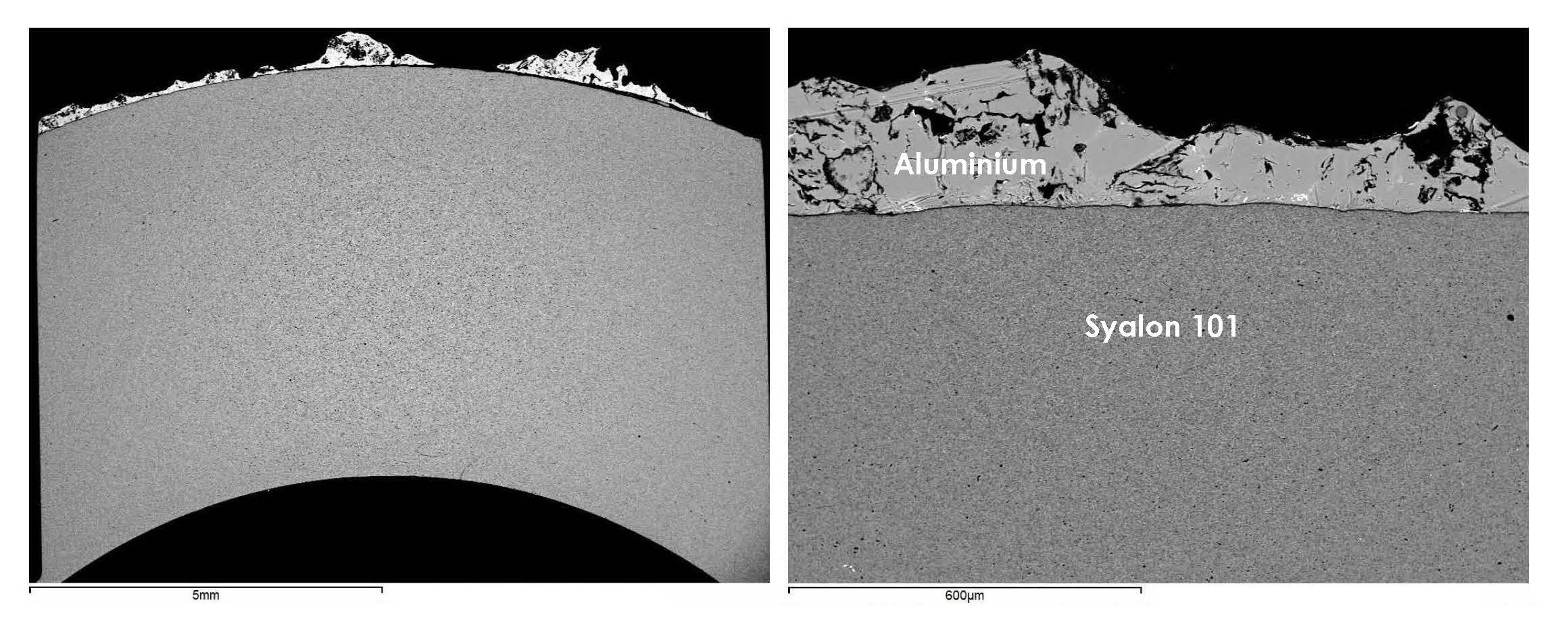

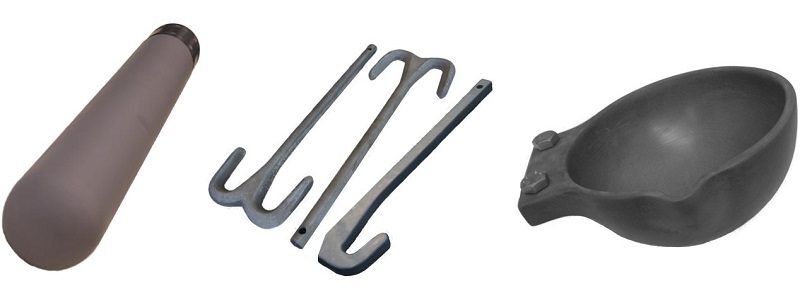

The effect of two step sintering on the fabrication and properties of sialon zrn composites has been studied. Syalon 501 is a composite grade silicon nitride based sialon ceramic developed to provide an. Custom made sialon products custom sialon products for use in molten aluminium such as high temperature crucibles galvanising tips and doceram silicon nitride welding pins sialon galvanizing hooks sialon welding pins. The new generation of sialon ceramics developed by sialon ceramics ltd has been shown to significantly improve the shock resistance and decrease wetting by molten aluminum making it highly attractive for the fabrication of crucibles tubes and fixtures used in metal smelting operations.

In metal forming sialon is used as a cutting tool for machining chill cast iron and as brazing and welding fixtures and pins particularly for resistance welding. International syalons produce a mixed α β sialon which is available as syalon 050. This implies that the physical properties of β sialon ceramics can be controlled using a sintering additive and can meet the requirements of bone repairing materials. Therefore β sialon ceramics have the potential for use in the fabrication of novel load bearing bone implants.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)