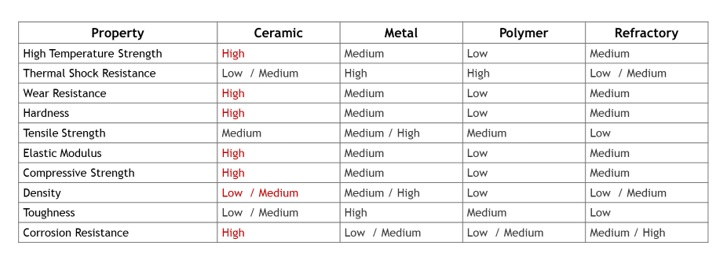

Sialon Ceramic Properties

Sialon st from mcdanel advanced ceramic technologies llc is a ceramic alloy which is iso structural with beta silicon nitride and contains aluminum and oxygen in solid solution.

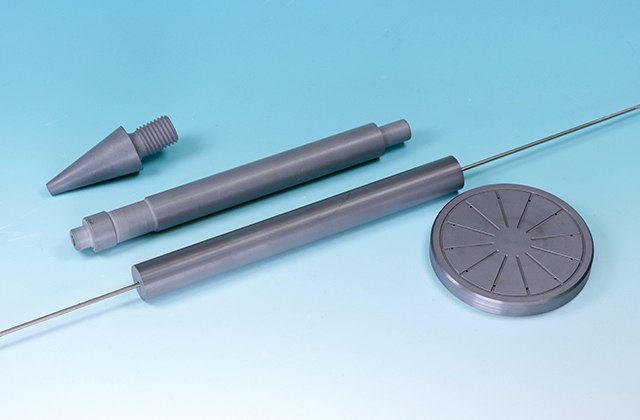

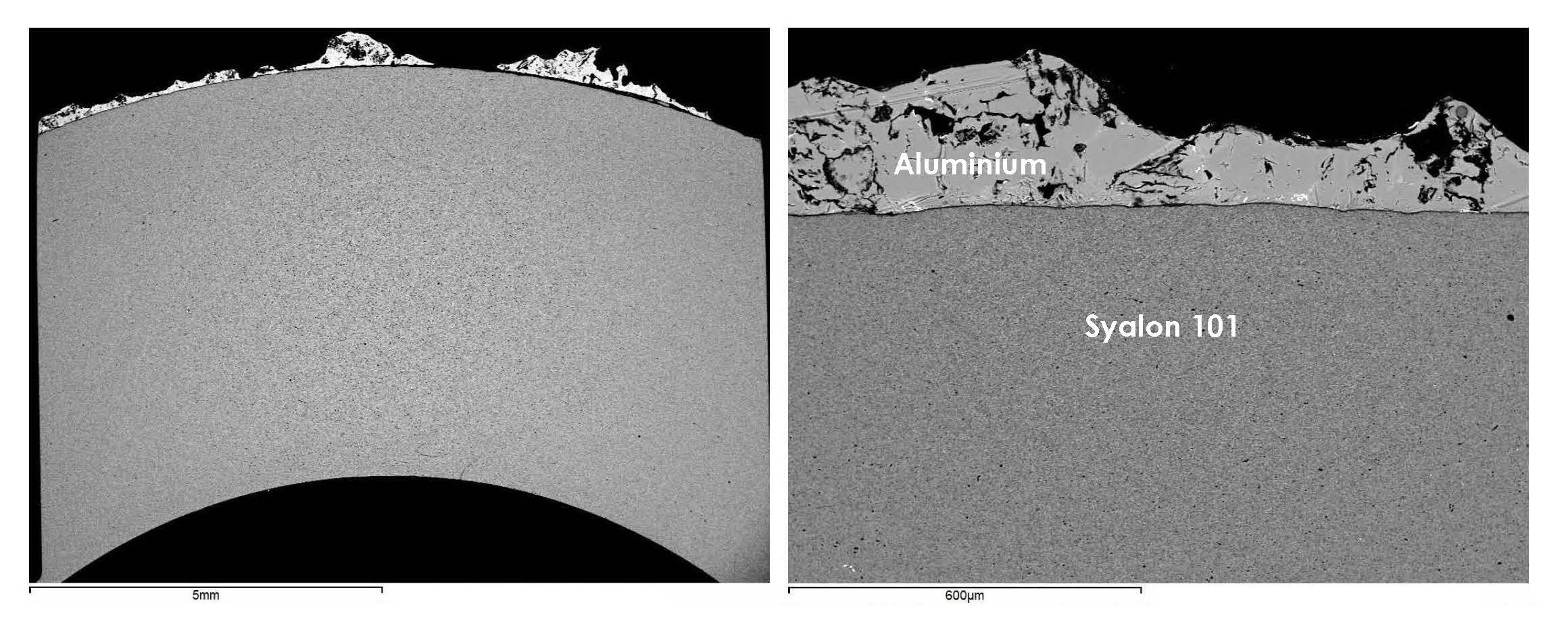

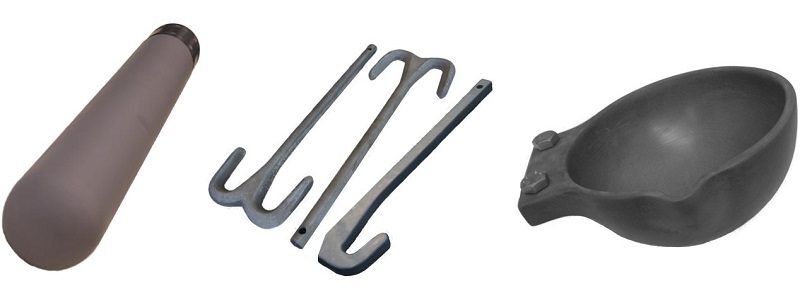

Sialon ceramic properties. 800 c with ceramic coating 1150 c without coating. A typical use is with handling of molten aluminium. 40 w m k 500 c. Syalon 501 is a composite grade silicon nitride based sialon ceramic developed to provide an electrically conducting advanced ceramic with the traditional silicon nitride properties of high strength toughness and hardness this allows syalon 501 to be electro discharge machined into more complex shapes than other types of silicon nitride without the need for expensive diamond.

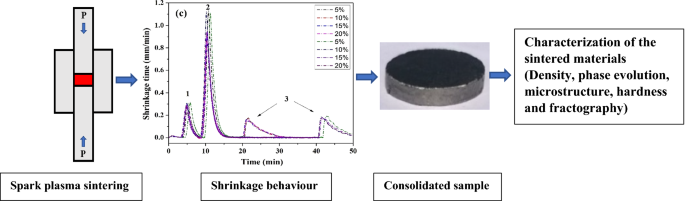

The partially stabilized α sialon ceramics have been tried to be applied in structural parts at high temperature because of their excellent mechanical properties. As alloys of si 3 n 4 sialons exist in three basic forms each form is isostructural with one of the two common forms of si 3 n 4 beta β and. What are sialon ceramics. The sintering aid used is an ain and al 2 o 3 mixture either pure or in combination with y 2 o 3 and or various rare earth oxides.

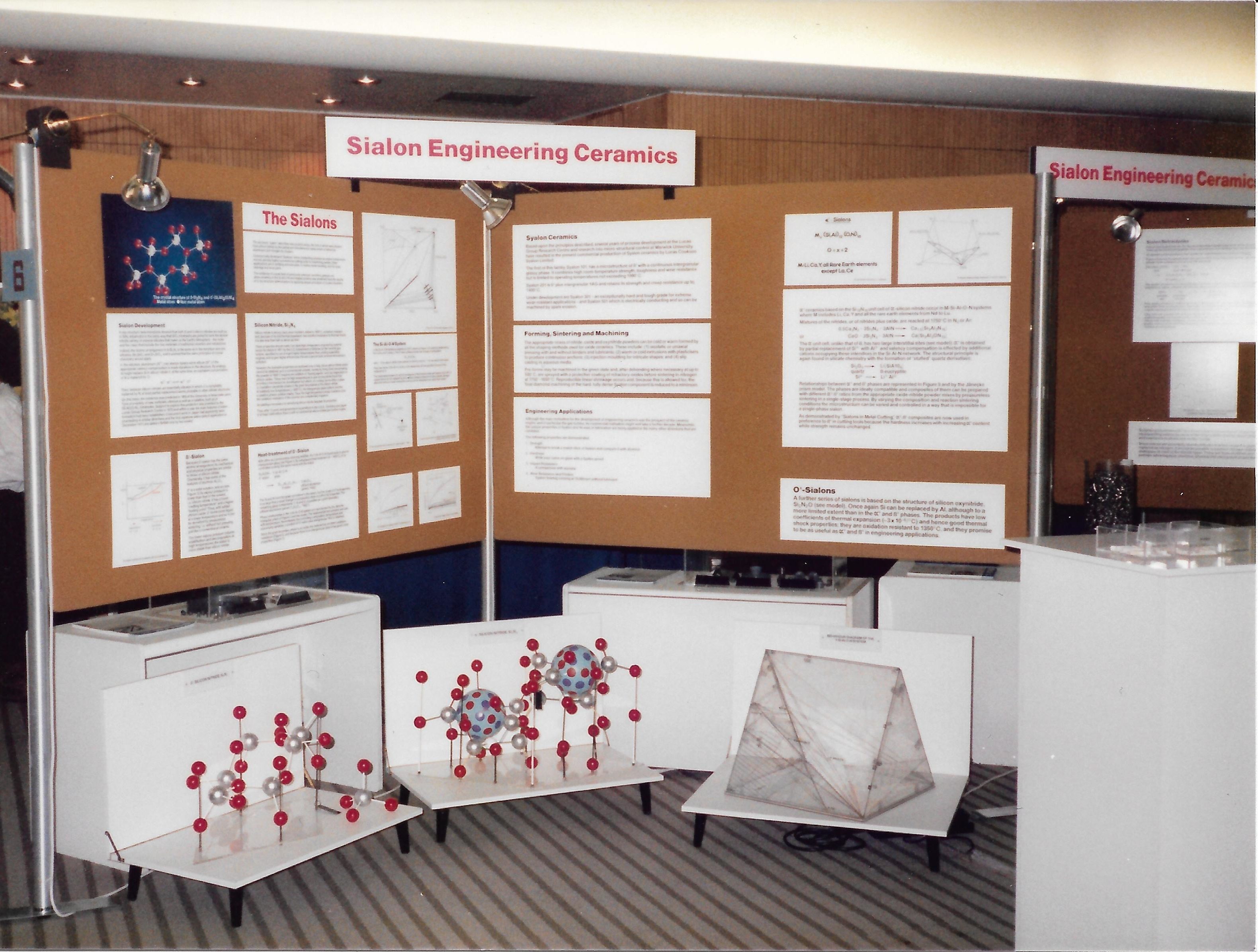

Sialons are ceramic alloys based on the elements silicon si aluminium al oxygen o and nitrogen n and were developed in the 1970s to solve the problem of silicon nitride si 3 n 4 being difficult to fabricate. To investigate the effects of y 2 o 3 on the physical properties and biocompatibility of β sialon ceramics β sialon ceramics were prepared with al si and α al 2 o 3 powders using a direct nitriding technique. As a sintering additive y 2 o 3 helps lower the sintering temperature and forms β sialon ceramics. The phase relations in and physical properties of sialon ceramics prepared by the hot isostatic pressing technique or by pressureless sintering with a sintering aid are reviewed.

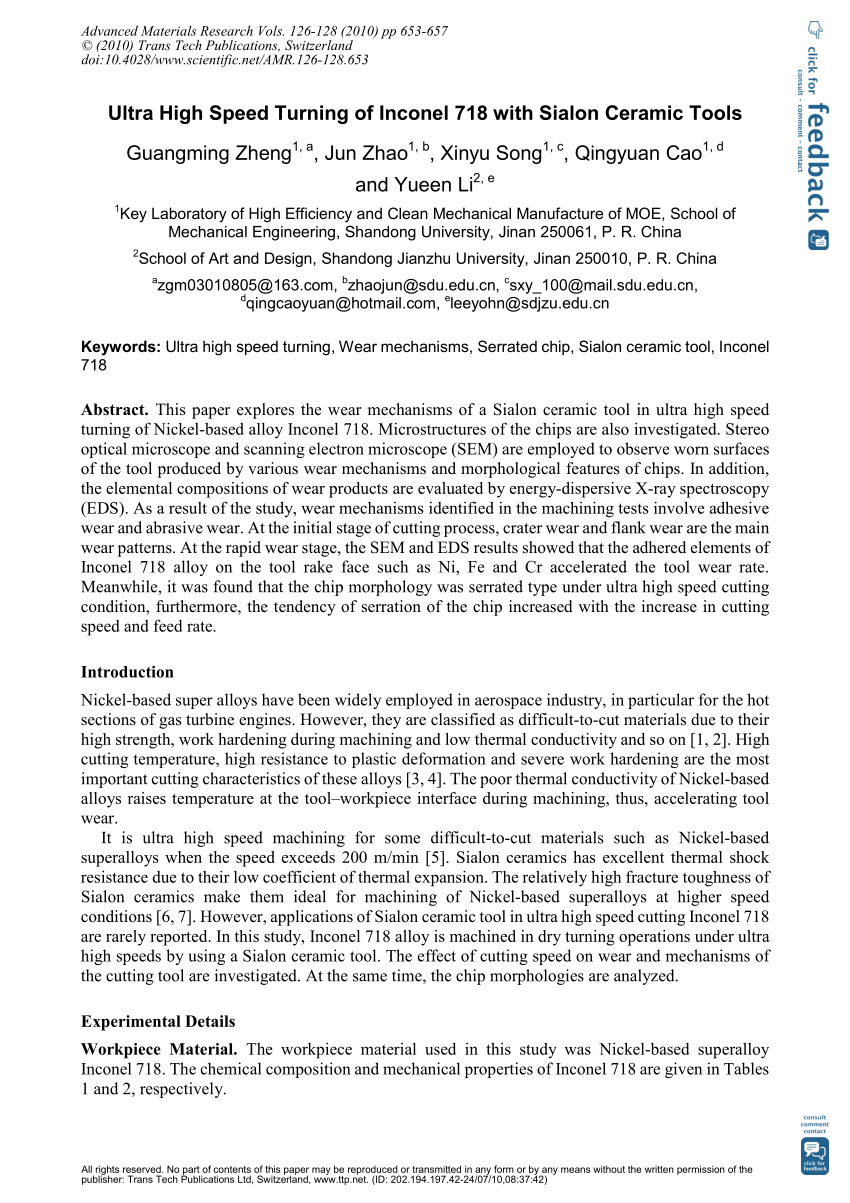

It is highly thermal shock resistant strong and is not wet or corroded by aluminum brass bronze and other common. In this study the physical and biological properties of the prepared. Ceramic coated or uncoated cast iron thermocouple protection tubes or custom built thermocouple assemblies for use in aluminium furnaces and baths. α β sialon ceramics silicon alumina nitride are some of the newest materials found in technical ceramics and are related to silicon nitrides.

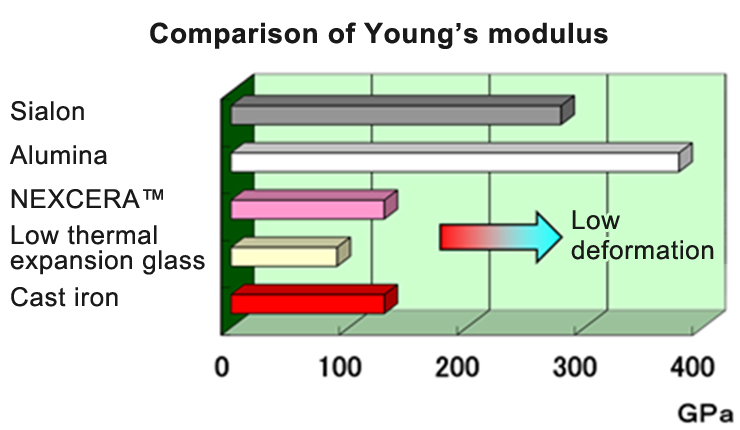

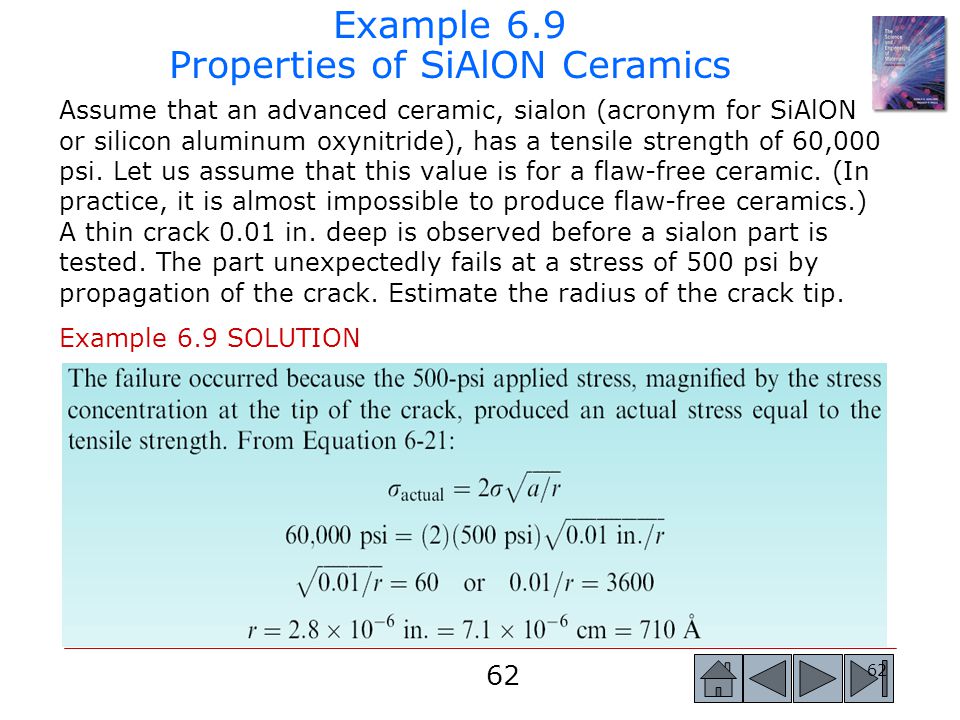

Consequently it exhibits a very desirable combination of the properties of both silicon nitride high strength hardness fracture toughness and thermal shock. Especially yb α sialon ceramics showed excellent oxidation resistance because the materials formed a dense oxidized protective layer with high melting point 3. Ceramtec employs α β sialon ceramics for the targeted design of mechanical properties.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)